産業運営のダイナミックな環境の中で、私たちのクライアントは、製造プロセスの基盤として長年機能してきた既存の生産設備が徐々にエスカレートする問題に直面する重要な岐路に立たされました...

産業運営のダイナミックな環境の中で、私たちのクライアントは、製造プロセスの基盤として長年機能してきた既存の生産設備が、急速に進化するビジネスの高まる要求に徐々に屈しているという重要な岐路に直面しました。市場機会が急増し、生産量が急上昇する中で、現在の機械の陳腐化が、さらなる成長と競争力を妨げる強力なボトルネックとして浮上しました。

私たちのクライアントは、主に三つの目標を明確にしました:生産効率を大幅に向上させること、市場の足跡を戦略的に拡大すること、そして労働コストを最適化することです。これに応じて、私たちの専門チームは徹底的かつ体系的な取り組みを行いました。私たちは包括的なプレゼンテーションと、私たちのプレミアム製品を強調した綿密に構成された計画を策定しました。厳密な比較分析が行われ、私たちの提供物と彼らの従来の設備を、スループット、信頼性、運用の簡便さなどの複数の重要な次元で対比しました。この詳細な分析は、クライアントに不均衡の明確な理解を提供し、彼らが根拠のあるデータに基づいた意思決定を行うことを可能にしました。

クライアントは、適切な注意を払って、最適な解決策を追求する中で、同時にいくつかの競合企業と関わっていました。しかし、私たちのアプローチは、共感的なクライアントエンゲージメントへのコミットメントによって際立っていました。私たちは単なる製品の特徴の列挙を避け、代わりに全体的な立場を採用しました。私たちは実用的で実行可能な解決策だけでなく、クライアントの根本的な懸念に対処するための安心感も提供しました。彼らの運営上の課題の根本原因を深く掘り下げることによって、単なる症状の修正ではなく、体系的な改善を目指す戦略を考案することができました。

クライアントに対する徹底的なバックグラウンド調査も実施されました。私たちの調査結果は、クライアントが地元の産業エコシステム内で卓越した確立されたターミナル工場であり、10年以上の広範な生産と販売の経験を誇っていることを明らかにしました。彼らのポートフォリオは、成功した国際貿易の取り組みで満ちており、彼らの財務的な強さと深い市場の洞察を強調しています。この詳細な理解を活用して、私たちは製品の推奨と実施フレームワークを調整し、クライアントの好意を得ることができました。

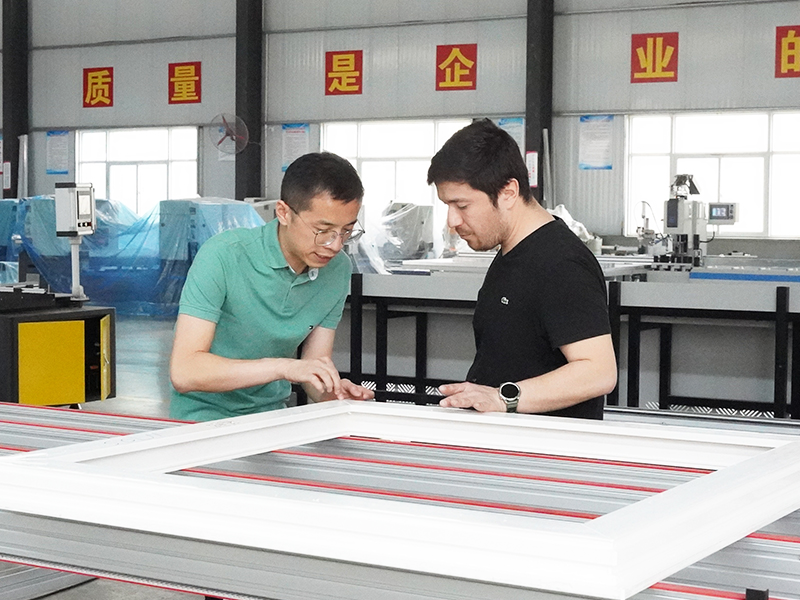

取引の利益に短絡的に焦点を当てるのではなく、私たちは強靭で長期的な関係を築くことを優先しました。私たちは、クライアントが過去に耐えた苦難を綿密に分析し、将来の潜在的な障害を積極的に予測することで、競合入札者との差別化を図りました。この戦略的な先見の明は実を結び、クライアントは私たちの能力に暗黙の信頼を寄せ、中国への訪問を決定し、私たちの施設を視察対象として選びました。この訪問中、私たちは製造工場の詳細なツアーを提供し、クライアントに私たちの生産能力を直接体験してもらいました。さらに、文化的な遠足を企画し、相互理解と友情の環境を育みました。

その後の議論では、機械の設置手順、運用ガイドライン、包括的なアフターサポートについて掘り下げ、両者の信頼をさらに強固にしました。この共有されたビジョンと揺るぎない信頼の文脈の中で、クライアントは最終的に大口の注文を出し、協力の成功の新たな段階を開きました。