Opis

Opis produktu

Cechy sprzętu

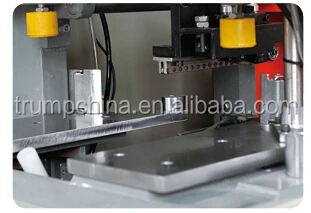

1.Maszyna do czyszczenia okien drzwi pvc o wysokiej prędkości z CNC jest specjalistycznym sprzętem do czyszczenia żużla spawalniczego pod kątem 90 stopni w drzwiach-oknach PVC.

2.Wykorzystuje najnowocześniejszy ekran dotykowy LCD, a z naszym specjalnym oprogramowaniem, menu interfejsu komputera pokazuje, monitor roboczy, ekran dotykowy, wygodna obsługa, regulacja narzędzia może być zakończona jednocześnie z programem.

3.Programowanie jest elastyczne i niezawodne. Główne części są importowane oryginalnie, co może zapewnić niezawodność działania. Maszyna ma system ochrony przed problemami i urządzenie alarmowe.

4.Ekran dotykowy może pokazać sytuację roboczą, co ułatwia operatorom testowanie problemów.

5.Dwie osie poruszane przez śrubę kulową.

6.Może być połączony z poziomą maszyną spawalniczą, aby stać się linią produkcyjną do spawania i czyszczenia narożników dla wielkich wyobrażeń i wysokiej wydajności.

1.Maszyna do czyszczenia okien drzwi pvc o wysokiej prędkości z CNC jest specjalistycznym sprzętem do czyszczenia żużla spawalniczego pod kątem 90 stopni w drzwiach-oknach PVC.

2.Wykorzystuje najnowocześniejszy ekran dotykowy LCD, a z naszym specjalnym oprogramowaniem, menu interfejsu komputera pokazuje, monitor roboczy, ekran dotykowy, wygodna obsługa, regulacja narzędzia może być zakończona jednocześnie z programem.

3.Programowanie jest elastyczne i niezawodne. Główne części są importowane oryginalnie, co może zapewnić niezawodność działania. Maszyna ma system ochrony przed problemami i urządzenie alarmowe.

4.Ekran dotykowy może pokazać sytuację roboczą, co ułatwia operatorom testowanie problemów.

5.Dwie osie poruszane przez śrubę kulową.

6.Może być połączony z poziomą maszyną spawalniczą, aby stać się linią produkcyjną do spawania i czyszczenia narożników dla wielkich wyobrażeń i wysokiej wydajności.

Specyfikacja

Model |

W przypadku urządzeń do kontroli nadprzestrzennej |

Moc wejściowa |

1,7 kW |

Zasilanie |

380V/50Hz |

Ciśnienie powietrza |

0,5~0,8 MPa |

Zużycie powietrza |

80L/min |

Prędkość obrotowa silnika |

2800obr./min |

Szerokość cięcia |

20~120 mm |

Wysokość cięcia |

30~120 mm |

Szerokość rowka rysunkowego |

3mm |

Głębokość rowka rysunkowego |

0,3 mm |

Ogólny wymiar |

2000*1820*1500 mm |

Waga |

700kg |

Profil Firmy

Jinan Truepro to producent maszyn do produkcji okien , maszyna do przetwarzania szkła izolacyjnego i maszyna do ścian osłonowych z dobrze wyposażonym sprzętem testowym i silną siłą techniczną. Dzięki szerokiemu asortymentowi, dobrej jakości, rozsądnej cenie i stylowym wzorom, nasze produkty są szeroko stosowane w branży budowlanej i innych branżach. Mamy nadzieję, że będziemy mogli z Państwem współpracować.

Wierzymy, że "TO JEST NAJLEPSZE, CO PASUJE NAJWIĘKSZEMU."

Wierzymy, że "TO JEST NAJLEPSZE, CO PASUJE NAJWIĘKSZEMU."

Każdą maszynę możemy dostosować do Państwa specjalnych wymagań.

Pakowanie i Dostawa

FAQ

1. Kiedy możemy zorganizować wysyłkę?

Zazwyczaj organizujemy wysyłkę w ciągu 15 dni po otrzymaniu zaliczki, ale maszyny na zamówienie powinny być realizowane w ciągu ponad 25 dni.

2. Co mogę zrobić, jeśli wystąpią problemy z moimi maszynami?

1) Jeśli Twoje maszyny są objęte gwarancją, możemy wysłać Ci bezpłatne części.

2) Możemy wysłać naszych inżynierów, aby naprawili Twoje maszyny

3. Czy zapewniacie szkolenia z obsługi sprzętu?

A: Tak. Możemy wysłać profesjonalnych inżynierów na miejsce pracy w celu instalacji sprzętu, regulacji i szkolenia w zakresie obsługi. Wszyscy nasi inżynierowie mają paszport.

4. Ile podstawowych maszyn będę potrzebował, jeśli zajmę się produkcją okien i drzwi aluminiowych?

1)piła do cięcia z podwójną głowicą

2)maszyna do frezowania otworów zamkowych

3)Freser końcowy

4)Automatyczna piła do cięcia złączek narożnych

5)Maszyna do łączenia narożników z pojedynczą głowicą

Zazwyczaj organizujemy wysyłkę w ciągu 15 dni po otrzymaniu zaliczki, ale maszyny na zamówienie powinny być realizowane w ciągu ponad 25 dni.

2. Co mogę zrobić, jeśli wystąpią problemy z moimi maszynami?

1) Jeśli Twoje maszyny są objęte gwarancją, możemy wysłać Ci bezpłatne części.

2) Możemy wysłać naszych inżynierów, aby naprawili Twoje maszyny

3. Czy zapewniacie szkolenia z obsługi sprzętu?

A: Tak. Możemy wysłać profesjonalnych inżynierów na miejsce pracy w celu instalacji sprzętu, regulacji i szkolenia w zakresie obsługi. Wszyscy nasi inżynierowie mają paszport.

4. Ile podstawowych maszyn będę potrzebował, jeśli zajmę się produkcją okien i drzwi aluminiowych?

1)piła do cięcia z podwójną głowicą

2)maszyna do frezowania otworów zamkowych

3)Freser końcowy

4)Automatyczna piła do cięcia złączek narożnych

5)Maszyna do łączenia narożników z pojedynczą głowicą